Milk is an essential food source that provides vital nutrients for the human body. It contains a complex blend of proteins, fats, carbohydrates, vitamins, and minerals that are crucial for growth, development, and overall health.

For centuries, humans have relied on the milk of domesticated animals, such as cows, buffaloes, sheep, and goats, to meet their nutritional needs.

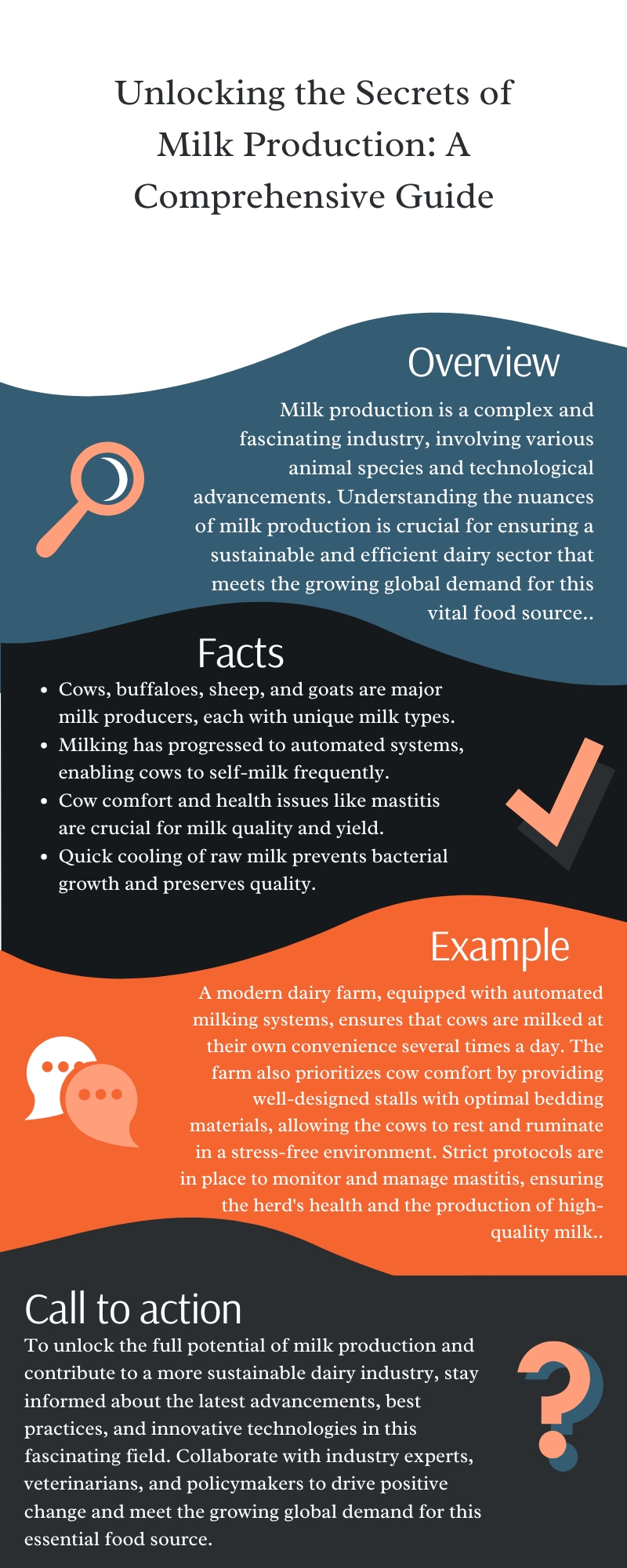

In this blog article, we will discuss the fascinating world of milk production, exploring the history, techniques, and advancements that have transformed this vital industry.

From the genetic improvements that have led to increased milk yields, to the innovative technologies that have revolutionized the milking process, we will uncover the secrets behind the production of this remarkable liquid.

Key Takeaways:

- Cows, buffaloes, sheep, and goats are the primary milk-producing animals, each with their own unique characteristics and milk compositions.

- Advancements in milking technologies, from traditional hand milking to automated systems, have revolutionized the dairy industry and improved efficiency.

- Maintaining optimal cow comfort and addressing issues like mastitis are crucial for milk quality, yield, and animal welfare.

- Rapid cooling of milk after milking is essential to prevent bacterial growth and ensure the safety and quality of the final product.

- The dairy industry must continue to evolve towards more sustainable and efficient practices to meet the growing global demand for milk and dairy products.

Milk Production Animals

1. Cows: The Global Dominance

Cows have long been the most widespread milking animal in the world, found on all continents. The modern lactating dairy cow has undergone significant genetic advancements since its domestication thousands of years ago.

Today’s cows can produce up to six times more milk than their primitive ancestors, with some individuals yielding as much as 14,000 liters per lactation cycle.

A. Reproductive Cycle and Lactation

B. Udder Anatomy and Milk Secretion

The cow’s udder is composed of glandular tissue containing milk-producing cells, known as alveoli. These alveoli are arranged in groups and are surrounded by capillaries that converge into larger milk ducts. As the alveoli secrete milk, the internal pressure rises, and the milk is forced into the larger ducts and down into the cistern, a cavity above the teat.

During milking, the release of the oxytocin hormone triggers the let-down reflex, causing the muscle-like cells surrounding the alveoli to compress and expel the milk through the capillaries and into the larger ducts.

C. Milking Frequency

2. Buffaloes: Significance in Asia and Africa

Other animals commonly used in both subsistence and industrial dairy farming include goats, sheep, and buffaloes. The milk of these animals is of great importance to rural communities in Asia and Africa, providing a valuable source of high-quality protein and other essential nutrients.

The buffalo, in particular, has been used in milk production for centuries and is the most common milk producer in Asia and certain areas of Africa. Buffaloes in India and China typically produce 450-500 kilograms of milk per lactation period, while specialized milking farms can achieve yields of over 1,700 kilograms. In Italy, buffalo milk production can reach up to 3,000 kilograms per lactation.

A. Milk Composition and Properties

The composition of buffalo milk differs from that of cow milk, with a significantly higher fat content, which can reach up to 13%. This higher proportion of saturated fatty acids gives buffalo milk a higher melting point compared to cow milk.

B. Milking Techniques

Milking buffaloes requires slightly different techniques than milking cows. Hand-milking is the most common method used on small, family-run farms, and it is essential to use a smooth and comfortable milking technique to overcome the higher resistance in the teat sphincter.

Buffaloes have also been successfully milked with machines, particularly in southern European countries like Italy, where dairy products made from buffalo milk, such as mozzarella cheese, are a staple in the local diet.

3. Sheep: Dairy and Meat Breeds

Among the numerous breeds of sheep, some are primarily kept for meat and wool production, while others are considered dairy breeds. While dairy breeds may not exceed 100 kilograms of milk production per lactation, some meat breeds can produce as much as 150-200 kilograms.

4. Goats: Adaptability and Hardiness

Goats are considered the first ruminants to be domesticated and originate from Asia. They are extremely hardy animals and can thrive in areas where it may be difficult for other animals to live. Unlike sheep, goats are not flock animals, and there are numerous breeds, but no specialized dairy breed.

Milking Technologies

1. Traditional Hand Milking

Hand milking continues to be a common practice on farms around the world, as it has been for thousands of years. Cows on smallholder farms often become accustomed to their familiar milker, and the let-down reflex is stimulated by the familiar sounds of milking preparations.

The milking technique involves using two opposing quarters of the udder at a time, with one hand pressing the milk out of the teat cistern, followed by a relaxation of the pressure to allow more milk to run down from the udder cistern.

2. Conventional Milking Systems

The basic principle of the milking machine is the extraction of milk from the teat by vacuum. The essential components of a milking machine include a vacuum pump, a vacuum vessel, a vessel for collecting milk, tea cups, and a pulsator.

A. Teat Cup Unit and Pulsation

B. Types of Milking Systems

The four teat cups, attached to a manifold called the milk claw, are held on the cow’s teats by suction and the friction between the teat and the teat cup liner.

Vacuum is alternately (alternate pulsation) applied to the left and right teats or, in some instances, to the front teats and rear teats. The application of vacuum to all four teats at the same time (simultaneous pulsation) is less common.

3. Automatic Milking Systems

Automated milking systems are a solution to the labor-intensive nature of traditional milking, offering dairy farmers with large herds reduced labor requirements, higher milk quality, improved animal health, and increased yield.

A. Cow-Driven Milking

In an automatic milking system, the emphasis is on the cow’s inclination to be milked in a self-service manner several times a day. When the cow wants to be milked, she walks to the milking station, where a transponder on the cow identifies it. If the cow was milked recently, she is directed back to the resting or feeding area.

B. Milking Process

The cow enters the automatic milking station, and an individual amount of concentrate is served. Sensors detect whether or not pre-milking has been carried out, and fore-milking is applied for a few seconds to ensure that sufficient milk is evacuated and the let-down reflex is activated. Teats are detected by lasers and a vision camera, and the milking process is initiated.

Mastitis and Cow Comfort

1. Mastitis: Prevalence and Impact

A. Causes and Symptoms

Mastitis can be caused by bacterial infections or trauma. When bacteria are growing, they release metabolites and toxins that stimulate the cow’s defense mechanisms, leading to inflammation.

2. Cow Comfort and Animal Welfare

The production of high-quality milk is closely linked to animal well-being, and cow comfort has been identified as one of the leading influences on both quality and yield. Cows housed in a comfortable environment are more likely to produce more milk and live healthier, longer lives.

A. The Five Freedoms

The five freedoms relate to the ideal states of the animal and include:

- Freedom from hunger and thirst

- Freedom from discomfort

- Freedom from pain, injury, and disease

- Freedom to express normal behavior

- Freedom from fear and distress

B. Factors Influencing Cow Comfort

Creating a comfortable environment for dairy cows is of great importance, both from an animal welfare and economic perspective. Factors such as the dimensions and type of bedding material used in the stalls can greatly impact the cows’ level of comfort.

3. Cow Longevity and Culling

Post-Milking Processes

Milk Cooling: Importance of Rapid Cooling

Efficient cooling of the raw milk after milking is the best way to prevent bacterial growth and ensure the quality and safety of the product.

A. Cooling Systems

Various cooling systems are available, ranging from in-can coolers for small producers to more sophisticated systems for larger operations. The choice of cooling system depends on the volume of milk produced.

B. Bacterial Growth and Temperature

It is crucial to maintain low temperatures during milk storage, as the activity of microorganisms can easily increase if the temperature is allowed to rise even a few degrees above the recommended storage temperature.

Conclusion

Producing larger quantities of milk in the long term requires all stakeholders in the dairy farming industry to learn to be more productive in ways that use fewer natural resources, safeguard animal well-being, and generate the necessary financial returns.

Dairy farmers are the primary actors in the milking of mammals, but they are also part of an intricate ecosystem that includes local veterinarians, other farmers, and various support services.

By understanding the complexities and advancements in milk production techniques, we can work towards a more sustainable and efficient dairy industry that meets the growing demand for this essential food source while respecting the welfare of the animals and the environment.

| Key Milk Production Statistics | |

|---|---|

| Cow Milk Production | Up to 14,000 liters/lactation |

| Buffalo Milk Production | 450-3,000 kg/lactation |

| Sheep Milk Production | 0.4-2.3 kg/ewe/day |

| Goat Milk Production | 400-1,300 kg/lactation |

| Clinical Mastitis Rates | 20-100 cases/100 cows/year |

| Subclinical Mastitis Rates | 5-35% of quarters infected |

FAQs

1. What are the primary milk-producing animals?

The primary milk-producing animals include cows, buffaloes, sheep, and goats. Cows are the most widespread and dominant milk producers globally, with modern dairy cows capable of producing up to 14,000 liters of milk per lactation cycle. Buffaloes are also significant milk producers, particularly in Asia and Africa, with milk that is higher in fat content compared to cow milk. Sheep and goats are other important milk-producing animals, often in areas where larger livestock are less suited.

2. How have milking technologies evolved?

Milk production has undergone significant technological advancements over the centuries. Traditional hand milking has given way to conventional milking systems that use vacuum and pulsation to extract milk efficiently. The latest developments in milking technology include automated systems that allow cows to be milked multiple times a day in a self-service manner, reducing labor requirements and improving animal welfare.

3. What factors influence milk quality and yield?

Maintaining optimal cow comfort and addressing health issues like mastitis are crucial for ensuring high-quality milk and maximizing yields. Factors such as the bedding material in stalls, freedom of movement, and access to feed and water all contribute to the well-being of dairy cows. Addressing the prevalence of mastitis, an inflammatory udder condition, is also essential for maintaining milk quality and production levels.

4. Why is rapid milk cooling important after milking?

Efficient cooling of raw milk immediately after milking is vital to prevent bacteria growth and ensure the final product’s safety and quality. Maintaining low temperatures during milk storage is crucial, as even a slight increase in temperature can lead to a rapid increase in microbial activity, which can compromise the milk’s characteristics and shelf life.